Tuesday, April 27, 2010

Monday, April 26, 2010

Golf’s Drive Towards Sustainability

By Michael Vogt, CGCS

The way I understand it, “Sustainability is meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

Click to view image in seperate window

In our industry of golf course management can the GCSAA take the role of leadership in an industry-wide initiative such as this? I’d like to elaborate on this and present sustainability leadership as an evolutionary practice for GCSAA, as most other industry stand-alone organizations soon realized from their experiences. As individual courses develop sustainability competencies, most will go through a series of phases, and the individual style that is appropriate for each phase needs to evolve as well, as we have learned. The apparent phases are: Learning, Alignment and Intrenchment.

Learning Phase

The majority of courses will be drawn into sustainability by both internal and external pressures. Ironically, competition is an important element. The more one golf course or club embraces sustainability the more other golf courses will become focused on the processes of sustainability. Most golf courses will therefore face an early stage where the club’s understanding of sustainability is limited; wherein both the superintendent and the entire host of course employees are learning about sustainability and what it means for the company by way of public awareness and recognition in the communities as well as any possible savings of resources. An early indicator that a golf course is entering the sustainability arena is when industry leaders and superintendents begin to talk and share information about sustainability at their local meetings and with peers in presentations. Public statements by the general manager and superintendent help signal to employees that sustainability is important, but it is organizational changes that facilitate broader learning at an individual course application

A typical, and often best change, is the creation of “sustainability” or “eco” teams that bring together employees from across the club organization. Since sustainability is a cross-functional and cross-organizational challenge the development of eco teams makes sense. All of the golf course’s business units (golf course, golf shop, restaurant and building maintenance) and functions need to explore the meaning of sustainability for their specific situations and how their actions impact other functions (synergy).

Leadership in the learning phase is organic, with sustainability champions emerging in the various club’s business units. Savvy leaders will engage and motivate employees by focusing on sustainability issues that align with employee values. The volunteer rates for green teams should be high because many employees want to feel that their work is contributing to not just the bottom line, but also a better world.

Alignment Phase

Self-starting green teams and voluntary sustainability programs like recycling, waste reduction, etc., are an early outcome from the learning phase. But at some point, the approach reaches its limits. By this time, the club has gained substantial understanding of sustainability in general and the specific sustainability issues facing the industry and the club specifically. Employees have probably also improved their workplace practices keeping a watchful eye on cleanliness and order in the workplace. However, further advanced sustainability requires coordinated action and alignment in the unique club’s ultimate goals.

To move the club forward, leaders must articulate a clear sustainability mission and vision for the whole organization. A good sustainability mission states what value the club brings to society and a commitment to address valid concerns about the environmental and social impacts created by the entire club. Many golf course properties will also officially recognize the sustainability champions from the previous phase and add specific sustainability roles to their existing functional duties.

For example, all operations at the Island Golf Club near Baton Rouge, Louisiana require a significant budget and like many golf facilities, efficient, sustainable and economical operations at the club are important. A plan to install an array of solar panels on the cart storage building that would power the cart building, main clubhouse, and golf shop as well as the tennis and pool clubhouse.

The second project entails a geothermal unit for the main clubhouse, which incorporated a second solar unit for the groundwater pump associated with the geo-thermal unit. As of November 15, 2009 the Island Golf Club’s solar system had generated more than 50,000 kWh with more than 63,000 pounds of CO2 emission offset.

The geothermal and solar projects are a significant change for the Island Golf Club and are intended to improve operational expense, sustainability as well as environmental stewardship. As of November 2009 there has been an estimated 54% reduction in utility costs at the club house. That is approximately $5,000 per month. The investment for these projects was approximately $252,000 for the solar projects and $90,000 for the geothermal unit project. Federal tax incentives exist for energy saving - sustainable projects like these. The Island Golf Club was able to use a federal tax incentive of 30% for both projects.

This type of leadership is like diplomacy, working to align partners and stakeholders toward common sustainability goals. GCSAA can act as a Sustainability Officer becoming a leading source for sharing industry wide sustainability Best Management Practices (BMPs), goals, policies, information and campaigns.

Leadership in this phase is often more difficult because it requires moving beyond the association’s gates into the field more often. GCSAA has a golden opportunity to work with golf courses, superintendents, general managers and other stakeholders to establish themselves as leaders in the field of Golf’s Drive for Sustainability.

Intrenchment Phase

The final phase of Sustainability is the very practices that are intrenched and engrained in the fabric of the club’s mission. Even today, very few companies have reached the final phase where sustainability practices become top-of-mind in the company culture, processes and systems. This, however, should be the end game – the pinnacle achievement – for all businesses. As mentioned in the opening, “Sustainability is meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

Ultimately, solving our sustainability problems will depend on inspirational ideas and innovative leadership that can change ways we do business. Let’s concentrate on finding and fostering the inspiration and start acting on it. GCSAA has in it’s hands a once in a generation opportunity to foster great change and align it’s membership for even greater recognition; lets hope their up to the task.

Friday, April 23, 2010

WAL-MART vs. our U.S. Federal Legislators

1. American spends $36,000,000 at Wal-Mart every hour of every day.

2. This works out to $20,928 profit every minute!

3. Wal-Mart will sell more from January 1 to St. Patrick's Day (March 17th) than Target sells all year.

4. Wal-Mart is bigger than Home Depot + Kroger + Target + Sears + Costco + K-Mart combined.

5. Wal-Mart employs 1.6 million people and is the largest private Employer.

6. Wal-Mart is the largest company in the history of the World.

7. Wal-Mart now sells more food than Kroger & Safeway combined; and keep in mind they did this in only 15 years.

8. During this same period, 31 supermarket chains sought bankruptcy.

9. Wal-Mart now sells more food than any other store in the world.

10. Wal-Mart has approx 3,900 stores in the USA of which 1,906 are Super Centers; this is 1,000 more than it had 5 Years ago.

11. This year 7.2 billion different purchasing experiences will occur at a Wal-Mart store. (Earth's population is approximately 6.5 Billion.)

12. 90% of all Americans live within 15 miles of a Wal-Mart.

To: The president and all 535 voting members of the Legislature.

1. The U.S. Post Service was established in 1775. You have had 234 years to get it right and it is broke.

2. Social Security was established in 1935. You have had 74 years to get it right and it is broke.

3. Fannie Mae was established in 1938. You have had 71 years to get it right and it is broke.

4. War on Poverty started in 1964. You have had 45 years to get it right; $1 trillion of our money is confiscated each year and transferred to "the poor" and for the most part they only want more.

5. Medicare and Medicaid were established in 1965. You have had 44 years to get it right and they are broke.

6. Freddie Mac was established in 1970. You have had 39 years to get it right and it is broke.

7. The Department of Energy was created in 1977 to lessen our dependence on foreign oil. It has ballooned to 16,000 employees with a budget of $24 billion a year and we import more oil than ever before. You had 32 years to get it right and it is an abysmal failure.

8. AMTRAK, taken over in 1970 by the U.S. Federal Government has lost money each year since 1970, 30.8 million in the first quarter of 2010. You have had 39 years to get AMTRAK self-sustaining as promised and guess what, it’s also broke.

Remember, deficit spending is a form of taxation without representation, because it increases the tax burden of generations who cannot yet vote (often because they are as yet unborn).

AND YOU WANT AMERICANS TO BELIEVE YOU CAN BE TRUSTED WITH A GOVERNMENT-RUN HEALTH CARE SYSTEM?

2. This works out to $20,928 profit every minute!

3. Wal-Mart will sell more from January 1 to St. Patrick's Day (March 17th) than Target sells all year.

4. Wal-Mart is bigger than Home Depot + Kroger + Target + Sears + Costco + K-Mart combined.

5. Wal-Mart employs 1.6 million people and is the largest private Employer.

6. Wal-Mart is the largest company in the history of the World.

7. Wal-Mart now sells more food than Kroger & Safeway combined; and keep in mind they did this in only 15 years.

8. During this same period, 31 supermarket chains sought bankruptcy.

9. Wal-Mart now sells more food than any other store in the world.

10. Wal-Mart has approx 3,900 stores in the USA of which 1,906 are Super Centers; this is 1,000 more than it had 5 Years ago.

11. This year 7.2 billion different purchasing experiences will occur at a Wal-Mart store. (Earth's population is approximately 6.5 Billion.)

12. 90% of all Americans live within 15 miles of a Wal-Mart.

I generally shop with local merchants based in my home town rather than our local Wal-Mart Super Center, I feel in some way that I am supporting the local economy and hard working families down the street from where I live. But I digress; no one can argue the fact that Wal-Mart is a superpower retailer; that much is certain. You may think that I am complaining, but I am really laying the ground work for suggesting that MAYBE we should hire the guys who run Wal-Mart to fix the U.S. economy.

1. The U.S. Post Service was established in 1775. You have had 234 years to get it right and it is broke.

2. Social Security was established in 1935. You have had 74 years to get it right and it is broke.

3. Fannie Mae was established in 1938. You have had 71 years to get it right and it is broke.

4. War on Poverty started in 1964. You have had 45 years to get it right; $1 trillion of our money is confiscated each year and transferred to "the poor" and for the most part they only want more.

5. Medicare and Medicaid were established in 1965. You have had 44 years to get it right and they are broke.

6. Freddie Mac was established in 1970. You have had 39 years to get it right and it is broke.

7. The Department of Energy was created in 1977 to lessen our dependence on foreign oil. It has ballooned to 16,000 employees with a budget of $24 billion a year and we import more oil than ever before. You had 32 years to get it right and it is an abysmal failure.

8. AMTRAK, taken over in 1970 by the U.S. Federal Government has lost money each year since 1970, 30.8 million in the first quarter of 2010. You have had 39 years to get AMTRAK self-sustaining as promised and guess what, it’s also broke.

Remember, deficit spending is a form of taxation without representation, because it increases the tax burden of generations who cannot yet vote (often because they are as yet unborn).

AND YOU WANT AMERICANS TO BELIEVE YOU CAN BE TRUSTED WITH A GOVERNMENT-RUN HEALTH CARE SYSTEM?

Tuesday, April 20, 2010

Estimating Turf Water Use, Part 2, How to Arrive at Sprinkler Run Times

By Michael Vogt, CGCS

In the first installment we calculated several variables that are necessary to arrive at how much water the plant may need in a given time. These calculations are needed to arrive at the irrigation systems ability to meet those needs.

It’s vital to know what the Plant Available Water (PAW) that will exist in the root zone, expressed in inches, as well as the Management Allowable Depletion (MAD) expressed as a percent. AD is a factor used to trigger an irrigation event. The formula for arriving at an Allowable Water Depletion is:

AD = PAW x MAD

AD = Allowable Depletion

PAW = Plant Available Water

MAD = Management Allowable Depletion

Distribution Uniformity

Distribution uniformity (DU) is the measure of how uniformly water is applied and made available over a given turf area. DU is expressed in percentage form and generally represents the major component of irrigation efficiency. DU is also a statistical value measuring uniformity of coverage, ie, a DU of .8 denotes a DU of 80%.

Irrigation efficiency is affected by both site management and equipment at the site. Uniformity is related to the design and mechanical performance of the irrigation system.

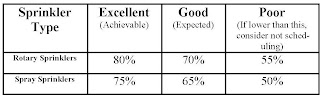

Estimated DU for sprinkler types

During an irrigation audit the nozzle size of a rotor sprinkler and operating pressure should be determined.The best way determined nozzle size is by using a drill bit inserted into the nozzle orifice.

Run time mulitplier as a function of DULQ

Flow

Station flow can be determined by the following equation:

GPM = 28.62 x D² x √P

GPM = Flow Rate of One Sprinkler

28.62 = Conversion Factor

D = Nozzle Diameter

P = Pressure at Nozzle

P = Pressure at Nozzle

Precipitation Rate (PR)

Precipitation Rate (PR) is the rate at which irrigation water is applied per unit of time, usually in inches per hour. Depending pressure, spacing and type of sprinkler selected, each individual sprinkler may have a different precipitation rate. If the flow rate of a specific irrigation area is known it is possible to estimate the average gross precipitation rate, also referred to as application rate.

PRgross = 96.3 x Q

HS x RS

PRgross = Gross Precipitation Rate in Inches per Hour

PRgross = Gross Precipitation Rate in Inches per Hour

96.3 = Conversion Factor

Q = Flow Rate from one Sprinkler

HS = Spacing Between Sprinkler Heads (ft)

RS = Spacing Between Rows of Sprinkler Heads (ft)

Net Precipitation Rate

Net precipitation rate is measured as the amount of water that actually reaches the turfgrass stand. The net is the gross less the losses that occur between the nozzle and the stand of turf.

PRnet = Vavg x 3.66

TR x CDA

TR x CDA

PRnet = Net Precipitation Rate (inches per hour)

Vavg = Average catch volume (milliliters)

3.66 = Constant that coverts milliliters to inches³

TR = Testing Run Time

CDA = Catch devise throat area (Inches²)

Run Time Multiplier

The Run Time Multiplier (RTM) is used to increase the number of minutes that would be required to apply a given amount of water depending on precipitation rate of the sprinkler and to compensate for a lack of perfect uniformity. The RTM also accounts for lateral water movement in the soil. RTM is based on the equation:

RTM = 1

0.4 + (0.006 x DULQ)

RTM = Run Time Multiplier

DULQ = Lower Quarter Distribution Uniformity (Percentage)

0.4 And 0.006 = Constants used because we catch water before it reaches the surface and can move laterally in the soil.

Base Run Time

To calculate Base Run Time for a sprinkler zone, the plant water requirement (PWR) is divided by the precipitation rate of the zone. Multiply by 60 to convert faction of an hour to minutes.

RTb = PWR x 60

PR

RTb = Base Run Time in Minutes (Minutes)

PWR = Plant Water Requirements (Inches)

PR = Precipitation Rate (Inches per Hour)

Example: where plant water requirements are 1.20 and precipitation rate is 0.59 then base run time would be 122 minutes per week.

Adjusted Run Time

To compensate for the lack of uniformity in the sprinkler zone, additional time will be required to be added to the irrigation schedule. The Run Time Multiplier (RTM) is used to calculate the total number of minute’s necessary based upon this equation:

RTadj = RTb x RTM

RTadj = Adjusted Run Time

RTb = Base Run Time

RTM = Run Time Multiplier

Example: If base run time is 122 minutes and the run time multiplier is 1.22 then the adjusted run time would be 149 minutes.

Maximum Run Time per CycleExample: If base run time is 122 minutes and the run time multiplier is 1.22 then the adjusted run time would be 149 minutes.

To arrive at a Maximum Run Time per Cycle to avoid run-off the best procedure is to time a zone to see how long it takes for water to run-off the site.

Maximum Run Time per Cycle = Infiltration Rate (Inches per Hour) x 60

Precipitation Rate (Inches per Hour)

Example: Where there is an infiltration rate of 0.75 inches per hour and a precipitation rate of 0.59 inches per hour the maximum run time would be 76 minutes before run off would occur.

Summary

The importance of the actual catchment test to determine the DULQ is critical in the above calculations to arrive at a runtime for weekly irrigation time and cycle requirements. Once the irrigation system is programmed with run times based on these equations you’ll benefit from reduced water usage and be confident that the irrigation system has been programmed with the greatest of accuracy. And when ask the question of how you arrived at your water use quantities you can honestly say that the system was programmed within guidelines set forth by the Irrigation Association to the strictest irrigation accepted standards and best management practices.

References:

1.Aronson, L.J., A. J. Gold, and R.J. Hull. 1987a. Cool Season Turfgrass Responses to Drought

Stress. Crop Science. 27:1261-1266

2.Carrow, Robert N. 1995. Drought Resistance Aspects of Turfgrasses in the Southeast

3.Web resource, http://www.fao.org/docrep/X0490E/x0490e06.htm accessed 8/14/2001

4.Mecham, Fortier, Moore, Berrett, Thompson, McKernan, LaFleur, Norum, 2003, Certified Golf Irrigation Auditor Manual

Tuesday, April 13, 2010

Estimating Turf Water Use, Part 1

By Michael D. Vogt, CGCS, CGIA

To understand how much water a turf plant requires is often a matter of intuition on the role of the golf course superintendent. Often that last inspection of the day is the deciding factor on how much water to apply to the turf that evening. With the advent of computer operated irrigation systems a percent increase here and decrease there is all that’s needed. Once the system is “dialed in” that’s the basic truth to the majority of irrigation scheduling. That’s one aspect of the art of greenkeeping, right?

Water can be applied with a degree of science as well as experience and the following is the step by step way to increase your technical knowledge on the science of water application on turfgrass. Whether you use these techniques or not it is critical to know for the simple reason that someday someone’s going to ask, “How did you arrive at the amount of water needed to keep the turf healthy with over watering?”

Evapotranspiration

The amount of water used by a section of turf on a golf course over any given period of time depends on local weather conditions, soil moisture availability and the characteristics of the turf species. Turf water use is also affected by the hydrogeological characteristics of the site and the infiltration rates of the soil. Soil infiltration rates can be measured with single or double ring infiltrometer.

One way to quantify the water needs of a particular type of turf is to identify its Plant Water Requirements (PWR). The PWR is the amount of water needed by the turf for growth, including the water lost through evapotranspiration (ET). ET is the amount of water transferred to the atmosphere by evaporation from soil and plant surfaces, plus the amount of water vapor released through the plant stomata via transpiration. For most golf course turf surfaces, transpiration is much greater than evaporation and therefore makes up the vast majority of ET.

Note: Confusion in the use of the term “ET” often exists. There are two industry accepted definitions of ET- the potential and the actual ET. Potential ET (sometimes given as “PET”) is defined as the ET rate that will occur for a given weather condition for “well watered grass”. Actual ET is equal to potential ET except where soil moisture is limiting, in which case actual ET is less than potential ET. Since the potential ET is of principal interest in determining turf water needs for irrigation, and the term “ET” is used in the industry to refer to potential ET, the term “ET” as used in this writing will mean potential ET unless otherwise specified.

Estimating Evapotranspiration (ET)

The most important factors contributing to ET rates are solar radiation, air temperature, wind speed and atmospheric moisture. Both local meteorology and soil characteristics can vary tremendously within an area the size of a typical golf course. The south side of an elevated area, with greater exposure to wind and radiation will have a greater potential ET rate than a slope with a northern exposure. Consistently, shaded areas will have lower ET rates than areas in full sun. These fine-scale variations in the physical environment are referred to as “microclimate.” ET rates calculated using regional weather data may provide a general indication of potential water use, but they should be adjusted up or down depending on the microclimates present in an individual golf course.

Double Ring Infiltrometer

Soil moisture availability is greatly influenced by soil type and texture. Sandy soils have high porosities but drain readily and do not have high available water holding capacities. Loam soils have the highest water holding capacities, whereas clay soils, although relative high in water contents, hold water so tightly that plants cannot remove the water for transpiration at lower water contents. A low area lying closer to the water table will require less irrigation than an area higher in the landscape because of upward flow of water (capillary rise) into the root zone from the water table, especially for the sandy loam soils.

There are many methods of estimating ET. Some of the more common approaches include obtaining data from outside sources, measuring ET, and calculating ET.

1. Outside sources of ET data. ET estimates can be obtained from commercial weather monitoring and forecasting operations. There are also publicly available weather data sets that often include estimates of ET. Values are usually given as a daily rate in mm per day or inches per day and are based on either evaporation pan data or an equation that estimates ET. This data is usually intended to describe conditions at a regional scale, and may over-or underestimate local conditions.

2. Measuring ET On Site. An alternative to using outside, regional ET estimates is the installation of one or more weather stations to measure on site ET. This alternative would be indicated, for example, when regional weather stations have been shown to consistently misrepresent local conditions. Some devices include:

a. On site weather stations (mostly directly connected into the irrigation system central computer).

b. Class A Evaporation pans. A U.S. Weather Service Class A evaporation pan is 122 centimeters in diameter and 25 centimeters deep and is supported 15 centimeters above the ground. The pans are filled with water and the amount of water that evaporates from the pan roughly correlates to the amount of water lost from turf due to evapotranspiration. The amount is not exactly the same; more water usually evaporates from the pan than is lost from the turf. A crop coefficient for evaporation pan data (Kc) is applied to the evaporation pan measurements to arrive at ET rates.

c. ET gages or Atmometers. These devices have a water reservoir connected by a wicking device to a surface such as a porous plate that mimics a leaf surface. The amount of water lost from the reservoir represents the ET for the given weather conditions. Rates will be less than from an evaporation pan since there is some resistance to flow through the wicking material. These are relatively inexpensive and should be located in the various microclimates found on the course.

3. Calculating ET. Regional weather operations and some measurement devices estimate ET using theoretical physical equations. These equations use available weather measurements, and normally make some assumptions with respect to local soil conditions and the nature of the plant canopy. It may be possible to obtain more accurate ET estimates by using local weather data, then adjusting the parameters of the ET equation to reflect the characteristics of the specific soil and vegetation present on the golf course.

1. Penman equation. This equation, often referred to as the Modified Penman equation, provides an estimate of evaporation from a free water surface. Four weather variables are required for this equation, solar radiation, wind, temperature and humidity. It is often used in place of pan evaporation. Since Penman and others have found that the equation also predicts well the ET from a 3-6" tall cool season grass that completely covers the ground, and is supplied with adequate water, it is sometimes referred to as a reference ET (ETo). A crop coefficient (Kc) for whatever species of grass is being irrigated is applied to the equation to get an estimate of the potential rate of ET for that crop.

2. Penman-Monteith equation. This equation predicts the ET from a crop directly.

The same four weather variables are required as the Penman equation plus a canopy conductance term that accounts for resistance to water movement within the reference plant. The specific canopy conductance values for individual crops are not commonly available; therefore, the Penman-Monteith equation is not used in practice as frequently as the modified Penman equation.

4. Blaney-Criddle. This equation was originated for use in the Western United States.

It uses temperature and day-length as the major independent variables for estimating ET. There are crop coefficients specific to the Blaney-Criddle equation available in the U.S. Soil Conservation Service (1970) handbook. It is recommended that the Blaney-Criddle equation be used for monthly ET estimation. This equation is simple but provides only a rough estimate. It may produce large errors under extreme weather conditions, especially outside of the Western United States where it was developed (Dunne and Leopold, 1978).

Crop Coefficients and Species Specific Water Use Rates

In addition to the physical environmental factors discussed above, the amount of water used by a turf canopy will also depend on the nature of the canopy itself. Within a species, water use needs vary diurnally and seasonally, and depend on the stage of development of the grass. “Crop coefficients” are a useful way of expressing relative water use efficiency numerically.

1. Species and Cultivar variations. Water use needs also vary among species, and cultivars of particular grass species can also vary in their water use rates. Warm season grasses tend to have lower water use rates while cool season grasses have higher rates. This is partly because cool season grasses use ET as a cooling mechanism.

Some turf species can have a lower comparative PWR and still require more water to maintain an acceptable quality than a species with a higher PWR. This is because some species have greater drought tolerance than others. The goal is to use grass species or cultivars that have a lower PWR and a high drought tolerance. A study by Aronson et al.

2. Crop Coefficients. Crop coefficients, as mentioned in the explanations above, are ratios of the potential ET of a particular crop, species or cultivar to a reference ET or evaporation rate. These coefficients are determined experimentally, often using weighing lysimeters under “unlimited soil water” conditions. Care must be used in the use of crop coefficients as the term is used for various references, Blaney-Criddle, Penman-Monteith, pan evaporation, and Penman evaporation equation. Crop coefficients will vary with the species of grass in question, the growth stage of the plants, the climate, the season, cutting height, and soil moisture stress, arriving at a single number to use as a crop coefficient can be problematic. Most golf course superintendents use crop coefficients in conjunction with experience to arrive at a consistent coefficient for their turf location and varieties.

A study of crop coefficients in the Northeast is the study by Aronson et al. This study compared measured ET rates for several species or cultivars with both pan evaporation and values predicted by the modified Penman equation. As studied the Penman equation and pan evaporation, rates varied both seasonally and from year to year. The authors concluded that using an averaged Kc value of 1.0 for the cool season turfgrass species studied would be adequate for irrigation scheduling. These values are higher than the typical values for turf of approximately 0.7 to 0.8.

Brown et al. (2001) in a study in Arizona found Kc values ranging from about 0.75 to 0.85 for Bermuda grass. These Kc values are for the Penman-Monteith equation for potential ET, not evaporation, and therefore would be expected to higher rather than lower than values based on the modified Penman equation or pan evaporation. A study by Carrow (1995) found that an average coefficient for tall fescue in the southeast for summer would be (0.79-0.82). This study also found the coefficients for turfgrass differed over the growing season.

Plant Available Water

Plant Available Water (PAW) represents the quantity of water stored within the root zone between the conditions of field capacity and the permanent wilting point. To solve for PAW as simple equation is this:

PAW = AW x RZ

PAW = Plant Available Water (Inches)

AW = Available Water (Inches of Water / Inches of Soil

RZ = Root Zone Depth

Management Allowed Depletion

Management allowed depletion (MAD) is the maximum amount of plant available water (PAW) expressed as a percent that the superintendent allows to be removed from the soil before irrigation occurs.

A value of 50% MAD is a reasonable overall value before irrigation will occur. Although, shallow root zones and sensitive plants such as Poa annua will require irrigation before the 50% threshold is reached.

Allowable Depletion

Now that we know the PAW and MAD we can apply an equation to arrive at the allowable depletion (AD):

AD = PAW x MAD

For example:If the MAD is 50% (0.50) and the PAW is 2.2 inches, then the approximately 1.10 inches of water could be used by the turf before the next irrigation (2.2 x 0.50 = 1.10 inches).

The next installment will discuss run time multipliers and how to figure run times based on these physical statistics.

References:

1.Aronson, L.J., A. J. Gold, and R.J. Hull. 1987a. Cool Season Turfgrass Responses to Drought

Stress. Crop Science. 27:1261-1266

2.Carrow, Robert N. 1995. Drought Resistance Aspects of Turfgrasses in the Southeast

3.Web resource, http://www.fao.org/docrep/X0490E/x0490e06.htm accessed 8/14/2001

4.Mecham, Fortier, Moore, Berrett, Thompson, McKernan, LaFleur, Norum, 2003, Certified Golf Irrigation Auditor Manual

Friday, April 9, 2010

Worst Management Practices

By Michael D. Vogt, CGCS, CGIA

Has common courtesy taken a backseat in modern business? I find it unlikely that any reader will respond favorably to that statement. I know that as I wrote it, I felt as if I was unfairly overstating the situation, yet I’m becoming convinced it has become a core value in most business organizations.

Lack of Courtesy

The venerable game of golf and the business of golf always possessed an air of civility and manners unlike most big awkward businesses in the U.S. I occasionally send email flyers to people in the golf business that might be interested in new ideas or services. Always at the bottom of the page if someone does not want to receive further emails there’s a note that describes, “To discontinue receiving McMahon Group newsletters and announcements, please respond with TERMINATE in the subject line and your email address with us will be deleted. Here’s one response, “Don’t you ever send me any of your junk, email, spam crap again.” I hate to think that this superintendent will be an inspiration to the next generation of golf business people. It’s far easier to type TERMINATE than that line and really lacks any courtesy whatsoever.

We usually think of things like “Core Values” and “Best Practices” as positive attributes of a businesses organizational culture. All too often we hear companies state that the employee is the businesses greatest asset. However, there are also negative organizational “Core Values” and “Worst Practices”. Spending some time to examine these, with the intent of highlighting their destructive attributes, in the hopes of alleviating them, is hopefully a productive use of time.

What behavior, repeated often enough and widely enough, could support the seemingly outrageous notion that, “Common courtesy has neither a place, nor a value, in the modern organization”, has become a common core value?

Courtesy in the Hunt

With the nations economy in the tank and many good people out of work, (and that does, or will apply to all of us, either in the past or certainly in the future) we can realize that the job hunt is stressful. Not knowing when we’ll land the next position is the source for constant anguish. Speaking plainly, the stress is enough to break up some relationships, turn to chemical and alcohol abuse and in rare cases it can even lead to suicide. Even when people don’t crumble under the strain, the burden of unemployment is, without a doubt, a heavy one.

Those in job transition quickly learn a few cold - hard facts about this age of the lean and (especially) mean organizations.

Truth # 1: They will rarely, if ever, receive a response, not even a form letter, to the dozens; if not hundreds of resumes they sent out in response to newspaper, trade journal or internet advertisements. Many years ago, a letter of acknowledgement was the norm. It was often a form letter, but it was recognition that at least the resume was received.

Most organization’s response is undoubtedly, that it would cost thousands of dollars to respond to the thousands of resumes they receive after an ad is published. They are unquestionably correct, it would indeed cost money to be courteous and acknowledge receipt of resumes they requested. The cost of courtesy is most certainly very high.

Truth # 2: Even if they do make it to the short list of potential candidates, after jumping through a series of telephone and in-person interview hoops, they should not hold their breath waiting for the final decision. Often it will require that they wait in growing angst and frustration until they can bear the pressure of suspense no more, and they phone their potential employer, numerous times, because their messages are not returned, until they happen by chance to get the person on the phone and they’re told shortly, “Oh yes, the job went to another candidate.”

One could argue, and many do, that the cost of responding to each and every resume is prohibitive, and far too high a price to pay for a mere gesture of courtesy, but when we get down to the short list of candidates, that argument becomes very weak indeed. What does it cost to send out a short note to the three or four finalists who weren’t selected for the position? Or better yet to phone each of them? Or have we arrived at the point where common courtesy really does have neither a place nor a value in our organizations?

The cost of courtesy is one reason for not getting back to people who are anxiously sitting by the phone, waiting for business organizations to enact a courtesy call. There is another possible reason for not calling a candidate who didn’t get the position. Businesses don’t call because they have an aversion to delivering bad news. They’d rather ignore the fact that someone is waiting to know if they can stop the conflicting dual tasks of hoping and worrying, because we don’t care enough to be courteous.

I’m not sure which of these reasons is the least desirable. I know that people who can’t deliver bad news have no place in any organization as managers. Furthermore business organizations that don’t have enough common courtesy to contact a short listed candidate to let them know to continue their job search don’t have a soul and can’t honestly say they treat people well.

Regardless of which is the lesser evil, the lack of common courtesy has regrettably become a common core value in business today not just in the job searching arena. There still remains ladies and gentlemen in our beloved business today but it saddens me to notice the lack of common courtesy invading business just when we need it most.

Please Remember

Courtesy; we refer to it in different ways, such as civility, good manners, good behavior, good conduct, politeness, decency, respect for others, thoughtfulness, kindness, and consideration. No matter what we call it, courtesy is NOT trivial. Here is how Edmund Burke (1729-1797) describes it, "Manners are of more importance than laws. Manners are what vex or soothe, corrupt or purify, exalt or debase, barbarize or refine us, by a constant, steady, uniform, insensible operation, like that of the air we breathe in."

Wednesday, April 7, 2010

Are you a Cheese Lover?

By Michael Vogt, CGCS

I believe the best selling book Who Moved My Cheese? to be one of the great books to identify with the new normal we are now experiencing in the golf business today. The book is a quick read and really illustrates with a magnifying glass what’s happening in our economy and our lives today.

Haw left behind Hem and started out in the vast maze looking for more cheese. As Haw moved though the maze looking for cheese he wrote on the wall of the maze some teachable facts:

“The more important your cheese is to you the more you want to hold on to it.”

“If you do not change you become extinct.”

“What would you do if you weren’t afraid?”

“Smell the cheese often so you know when it’s getting old.”

“Movement in a new direction helps you find new cheese.”

“When you move beyond your fear, you feel free.”

“Imagining myself enjoying new cheese even before I find it, leads me to it.”

“The quicker you let go of old cheese, the sooner you find new cheese.”

“It is safer to search in the maze than remain in a cheeseless situation.”

“Old beliefs do lead you to new cheese.”

“When you see that you can find and enjoy new cheese, you change course.”

“Noticing small changes early helps you to adapt to the bigger changes that are to come.”

Business is like cheese! I look at our industry, the business of golf, as one not unlike the story of these two mice and two little people. There are those that embrace the fact that someone will replenish the cheese supply if we just wait, things will get back to normal. Then there are the people that will seek out the new supplies of cheese. Looking for new cheese is not easy, but a more bountiful stash of cheese may be your reward.

If you’re wondering what happened in the end, Hem joined his two mouse friends at a new pile of cheese though much searching and determination. Haw finally saw the writing on the wall and followed Hem’s trail through the maze to the new and delicious stash of cheese. And finally we leave these cheese eaters feasting on cheese but secure in the knowledge that we need to smell and be aware of changing cheese conditions because when the cheese starts changing it is a call to look for replacement cheese.

Monday, April 5, 2010

What the hell is TRIZ

By Michael Vogt, CGCS

TRIZ (pronounced like Treez) is a problem solving method based on logic and data, not intuition, which may accelerate the ability to solve problems in a different and more creative way. "TRIZ" is the (Russian) acronym for the "Theory of Inventive Problem Solving." G.S. Altshuller and his colleagues in the former U.S.S.R. developed the method between 1946 and 1985. TRIZ is the study and theory of the patterns of problems and solutions.

TRIZ is spreading into the corporate world on many paths. TRIZ is increasingly used alongside the Six Sigma processes, in project management, customer satisfaction and risk management systems, and in many organizational initiatives.

How can TRIZ apply to the world of golf course management? We all know that problem solving relies on a relatively small set of solution patterns. For instances, when the superintendent has a problem or task the first reaction is to break the problem into small sets of easily accomplished tasks; like aerification of greens.

Figure 1 Greens Aerification

In Figure 2 above, the red arrows represent transformation from one formulation of the problem or solution to another. The two red arrows represent analysis of the problems and analytic use of the TRIZ databases. The blue arrow represents thinking by analogy to develop the specific solution. This four-step problem solving approach forces the user to overcome inherent psychological bias that is typically referred to as “psychological inertia” (we get easily stuck in how we normally “think”).

Example: Fertigation, hydraulically driven reels, high lift rotary mower blades, Toro Hydroject aerifier.

Whether you know it or not you use the basic principals of TRIZ for most of your golf course maintenance projects and problems. But not so fast - TRIZ theory gets into the problem solving methods even further. TRIZ research began with the hypothesis that there are universal principles of creativity that are the basis for creative innovations that advance technology. If these principles could be identified and codified, they could be taught to business leaders to make the process of creativity more predictable. The short version of TRIZ is:

“Somebody someplace has already solved this problem (or one very similar to it.)

Creativity is now finding that solution and adapting it to this particular problem."

There are three primary fundamentals of the TRIZ theory:

• Problems and solutions are repeated across industries and sciences. The classification of the contradictions in each problem predicts the creative solutions to that problem.

• Patterns of technical evolution are repeated across industries and sciences.

• Creative innovations use scientific effects outside the field where they were developed.

Much of the practice of TRIZ consists of learning these repeating patterns of problems and solutions and then applying the general TRIZ patterns to the specific situation that confronts the problem solver. The simple graphic in Figure 2 below describes this process.

Figure 2

In Figure 2 above, the red arrows represent transformation from one formulation of the problem or solution to another. The two red arrows represent analysis of the problems and analytic use of the TRIZ databases. The blue arrow represents thinking by analogy to develop the specific solution. This four-step problem solving approach forces the user to overcome inherent psychological bias that is typically referred to as “psychological inertia” (we get easily stuck in how we normally “think”).

Examples of Golf Industry and Change of Thinking

For example, a powerful demonstration of this method might come from the turf chemical industry. Hypothetically, a new group of information suggests that Garlic can control turf pathogens. Low concentrations of garlic extract can be safely applied to turf and control a wide range of turfgrass harming fungi. Today we’re studying the specific problem; can the turf industry find an ecological friendly way to keep turf from fungal infection. The general problem is a low cost, easily applied method to keep turf “fungi – free”. The general solution in this case might be a natural garlic product applied to the turf canopy. And the specific solution is elimination of dollar spot and brown patch without using expensive, ecologically unfriendly chemical compounds. I am not saying that garlic extract will eliminate or replace Daconil; I am just using this example of looking at a problem with a new theory that might augment a particular line of reasoning.

Another two great examples of general problem solving at the highest level was perhaps the chemistry behind the Aliette® brand fungicide; it is the only fungicide to deliver true, two-way systemic protection against certain turf pathogens. With multiple modes of action, Aliette® attacks fungi at multiple growth stages for better overall fungal control. Aliette’s® unique double action not only attacks and controls fungi on contact, but also stimulates the plant's own defense mechanisms. In addition to Aliette®, Heritage®, the active ingredient, azoxystrobin, belongs to a class of fungicides named strobilurins. This class of fungicide possesses a mode of action, which inhibits mitochondrial respiration in fungi, stopping their energy supply. Imagine this discovery, natural occurring woodland fungi use to treat fungi! Although these two chemistries are older, consider, Civitas, and its new mode of action has many in the turf industry reconsidering the turf plants ability to ward off disease within the plant itself, not unlike Aliette® but having chemistry far safer than that of Aluminum tris.

The 40 Principals

In the course of solving any one problem, one TRIZ tool or many can be used. The 40 Principles of Problem Solving are the most accessible "tool" of TRIZ. These are the principles that were found to repeat across many fields, as solutions to many general contradictions, which are at the heart of many problems.

A fundamental concept of TRIZ is that contradictions should be eliminated. TRIZ recognizes two categories of contradictions:

Technical contradictions are the classical engineering "trade-offs." The desired state can't be reached because something else in the system prevents it. In other words, when something gets better, something else gets worse. Classical golf course examples include:

• Growth regulators reduces mowing (good), Must re-apply throughout the season and suffer a trampoline affect after last seasonal application (bad)

• Controlled release nitrogen feeds the plant slower (good), but costs more than soluble forms of nitrogen (bad)

• Pre-emergent herbicides use to stop annual grassy weeds from germinating also stops desirable seed from germinating

Physical contradictions, also called "inherent" contradictions, are situations in which one object or system has contradictory, opposite requirements. Everyday examples abound:

• Trees on golf courses are visually stunning, however, the more trees on the course the more difficult it is to grow turf.

• More play on a golf course equals more revenue, but more play slows the speed to which it takes to complete a round.

Several examples of common golf business contradictions:

• We need to reduce labor costs on the golf course, but maintain current levels of playing conditions.

• Our 100 year old club needs to attract new members; regardless of a new club with better facilities for the same cost just one mile away.

• Native areas on the golf course reduce mowing and other maintenance but can slow play with golfers looking for lost balls.

TRIZ research has identified 40 principles that solve the Technical / Tradeoff contradictions and principles of separation that solve the Physical / Inherent contradictions. Additional examples include:

• School administrators: Creativity has been greatly enhanced in situations ranging from allocation of the budget for special education to building five schools with funding only for four, to improving racial harmony in the schools.

• Waste processing: Dairy farm operators could no longer dry the cow manure due to increased cost of energy. TRIZ led the operators to a method used for the concentration of fruit juice, which requires no heat.

• Warranty cost reduction: Ford used TRIZ to solve a persistent problem with squeaky windshields that was costing several million dollars each year. Previously, they had used TRIZ to reduce idle vibration in a small car by 165 percent, from one of the worst in its class to 30 percent better than the best in class.

A Description and Examples of the 40 Inventive Principals and the TRIZ Matrix

Use these 40 Inventive Principals with the TRIZ matrix. On the pdf downloadable TRIZ matrix sheet find the intersect of your specific situation and search the far right column for the Inventive Principals that apply to your specific problem or process. The following is the 40 basic rules to the process of TRIZ problem solving (Inventive Principals, far right hand column) with example(s) for each principal.

1. Segmentation

Divide an object into independent parts.

Example: Golf course syringe hoses can be joined together to form any length needed.

2. Extraction

Extract (remove or separate) a "disturbing" part or property from an object, or extract only the necessary part or property.

Example: Most irrigation computers will deliver run-times based on certain factors (evapotranspiration, angle of incidence, type of soil, variety of turf), most superintendents disable this feature.

3. Local Quality

Have different parts of the object carry out different functions and place each part of the object under conditions most favorable for its operation.

Examples: A pencil and eraser in one unit.

4. Asymmetry

Replace a symmetrical form with an asymmetrical form if an object is already asymmetrical, increase the degree of asymmetry.

Example: While spreading moist topdressing sand through a symmetrical spreader, the sand forms an arch or bridge above the opening, causing irregular flow. A bin of asymmetrical shape or conveyor belt eliminates the arching effect.

5. Combining

Combine in space homogeneous objects or objects destined for contiguous operations or combine in time homogeneous or contiguous operations.

Example: A greens aerifier has an attachment to windrow plugs for ease of removal.

6. Universality

Have the object perform multiple functions, thereby eliminating the need for some other object(s).

Examples: An irrigation computer that gathers weather data and soil moisture data and calculates water needs for the turf plant. DryJect® machine aerifies topdresses and applies soil amendments in one pass.

7. Nesting

Contain the object inside another which, in turn, is placed inside a third object. Pass an object through a cavity of another object.

Examples: The old greens dew whips that stored inside an aluminum tube for transport, or a mechanical pencil with lead stored inside.

8. Counterweight

Compensate for the object's weight by joining with another object that has a lifting force. Compensate for the weight of an object by interaction with an environment providing aerodynamic or hydrodynamic forces.

Example: A rear wing in racing cars which increases pressure from the car to the ground.

9. Prior counter-action

Perform a counter-action in advance if the object is (or will be) under tension, provide anti-tension in advance.

Examples: Reinforced pre-stressed concrete column. Hollow vertical turbine pump thought the motor shaft.

10. Prior action

Carry out all or part of the required action in advance. Arrange objects so they can go into action in a timely matter and from a convenient position.

Example: Install a pressure relieve valve (Cla-Val) on a pump station to protect components from high water pressure.

11. Cushion in advance

Compensate for the relatively low reliability of an object by countermeasures taken in advance.

Example: Grinding a relief on a reel to only have to grind a small portion of the reel blade surface in the future.

12. Equipotentiality

Change the working conditions so that an object need not be raised or lowered.

Example: Build a loading dock or ramp to load equipment on trailers or truck beds to transport on and off site.

13. Inversion

Instead of an action dictated by the specifications of the problem, implement an opposite action. Make a moving part of the object or the outside environment immovable and the non-moving part movable. Turn the object upside-down.

Example: Abrasively cleaning parts by vibrating the parts instead of the abrasive.

14. Spheroidality

Replace linear parts or flat surfaces with curved ones; replace cubical shapes with spherical shapes. Use rollers, balls spirals or replace a linear motion with rotating movement; utilize a centrifugal force:

Example: The difference between a PlanetAir machine and a conventional turf / greens slicer that slices in a straight line.

15. Dynamicity

Make an object or its environment automatically adjust for optimal performance at each stage of operation. Divide an object into elements which can change position relative to each other. If an object is immovable, make it movable or interchangeable.

Examples: A flashlight with a flexible gooseneck between the body and the lamp head. A rotary mower with many floating decks to mow contours more evenly opposed to a single fixed rotary deck.

16. Partial or overdone action

Figure 3 Tee jet Air Induction Nozzle

If it is difficult to obtain 100% of a desired effect, achieve somewhat more or less to greatly simplify the problem:

Examples: Fine droplets in a spray pattern guarantee good coverage (high pressure, lower volume) but have high drift potential. Nozzles designed for greens spray have an air induction system that greatly reduces spray drift and delivers a fine spray pattern.

17. Moving to a new dimension

Remove problems with moving an object in a line by two-dimensional movement (i.e. along a plane). Use a multi-layered assembly of objects instead of a single layer. Incline the object or turn it on its side.

Example: A stacked bowl vertical turbine pump rather than a single stage centrifugal pump.

18. Mechanical vibration

Set an object into oscillation. If oscillation exists, increase its frequency, even as far as ultrasonic. Use the resonant frequency. Use ultrasonic vibrations in conjunction with an electromagnetic field.

Example: When spin grinding a reel; the stone and the spinning reel have a frequency that matches the diameter and thickness of the metal blades on the reel. The correct frequency will accomplish the job better and faster.

Figure 4 Reel Grinder

19. Periodic action

Replace a continuous action with a periodic (pulsed) one if an action is already periodic, change its frequency, use pulsed between impulses to provide additional action.

Examples: An impact wrench loosens corroded nuts using impulses rather than continuous force. A warning lamp flashes so that it is even more noticeable than when continuously lit.

20. Continuity of a useful action

Carry out an action continuously (i.e. without pauses), where all parts of an object operate at full capacity. Remove idle and intermediate motions.

Example: When a reel drops to the turf surface it engages the reels automatically when lowered.

21. Rushing through

Perform harmful or hazardous operations at very high speed.

Example: The up and down movement of an aerifier tine is potentially harmful to turf at slower speeds causing turf to be pulled away from the soil, a fast moving tine is less apt to injure turf.

22. Convert harm into benefit

Utilize harmful factors or environmental effects to obtain a positive effect. Remove a harmful factor by combining it with another harmful factor. Increase the amount of harmful action until it ceases to be harmful.

Example: A USGA specification green is waterlogged, causing turf to wilt, with no air holding capacity for root respiration, introducing heavy irrigation will break the false water table and drain the green to normal air / water ratio.

23. Feedback

Introduce feedback, if feedback already exists, reverse it.

Examples: Water pressure and volume from an irrigation system is maintained by sensing output pressure and flow and turning on a pump if these parameters are too low. If the system detects high flow (like a mainline leak), the system will shut-down. A golf course sprayer moves up and down hill and maintains constant pressure and volume based on forward and reverse feedback (based on speed, pressure and volume).

24. Mediator

Use an intermediary object to transfer or carry out an action. Temporarily connect an object to another one that is easy to remove.

Examples: Tailoring a walking greens mower to a specific set of greens with a motorized cart. A material handler can move sand from a sand storage area and spread sand within the bunker.

25. Self-service

Make the object service itself and carry out supplementary and repair operations.

Examples: Tires filled with a special compound to seal small leaks. A filter system on an irrigation pump station, back-flushes itself when flow and downstream pressure is dissimilar by a predetermined factor.

26. Copying

Use a simple and inexpensive copy instead of an object which is complex, expensive, fragile or inconvenient to operate or replace an object by its optical copy or image. A scale can be used to reduce or enlarge the image. If visible optical copies are used, replace them with infrared or ultraviolet copies.

Examples: Find out stress areas on turf with the use of infrared red photos. As-Built drawings reduced to booklet size for irrigation service and repairs.

27. Inexpensive, short-lived object for expensive, durable one

Replace an expensive object by a collection of inexpensive ones, forgoing properties (e.g. longevity).

Examples: Disposable shop towels, plastic spray nozzles, packing rings on pump motors, plastic hydraulic motor couplings to reel drive on triplex greens mowers.

28. Replacement of a mechanical system

Replace a mechanical system by an optical, acoustical or olfactory (odor) system. Use an electrical, magnetic or electromagnetic field for interaction with the object.

Example: Magnetic bedknives, magnetic bedknife grinding tables, barcodes on equipment for servicing requirements.

29. Pneumatic or hydraulic construction

Replace solid parts of an object by gas or liquid. These parts can use air or water for inflation, or use air, water or hydrostatic cushions.

Figure 5 Toro Hydroject Aerifier

30. Flexible membranes or thin film

Replace traditional constructions with those made from flexible membranes or thin film. Isolate an object from its environment using flexible membranes or thin film.

Examples: To prevent water evaporation from plant leaves, polyethylene spray is applied. After a while, the polyethylene hardened and plant growth improved, because polyethylene film passes oxygen better than water vapor. Reverse osmosis membrane for water treatment.

Examples: To prevent water evaporation from plant leaves, polyethylene spray is applied. After a while, the polyethylene hardened and plant growth improved, because polyethylene film passes oxygen better than water vapor. Reverse osmosis membrane for water treatment.

31. Use of porous material

Make an object porous or add porous elements (inserts, covers, etc.) If an object is already porous, fill the pores in advance with some substance.

Example: The use of porous concrete to add hard surface parking areas without increasing drainage capabilities. The addition of the gavel layer below the sand layer in greens construction to move water out of water saturated sand.

Figure 6 USGA Specification Green Profile

32. Changing the color

Change the color of an object or its surroundings or change the degree of translucency of an object or processes which are difficult to see. Use colored additives to observe objects or processes which are difficult to see if such additives are already used, employ luminescent traces or tracer elements.

Examples: To check to see if a drainage system is functioning properly add a dye to the water and time its travel. Add reflectors dots or floor stripes inside maintenance building to locate parking areas for equipment, designate safety areas and mark stairways and curbs.

33. Homogeneity

Make those objects which interact with a primary object out of the same material or material that is close to it in behavior.

Examples: The metal at the bottom of a flagstick (ferule) is made out of a metal that is similar in hardness to a metal hole-cup. The hardness and composition of steel in reel mower bedknives and reels.

34. Rejecting and regenerating parts

After it has completed its function or become useless, reject or modify (e.g. discard, dissolve, evaporate) an element of an object. Immediately restore any part of an object which is exhausted or depleted.

Examples: Reel mower bedknives, new nozzles for irrigation heads, packaging for turf chemicals that dissolve in water.

35. Transformation of the physical and chemical states of an object

Change an object's aggregate state, density distribution, degree of flexibility, temperature.

Example: Changing the pH of water to increase the efficacy of the spray mix. Add gypsum to irrigation water to help mitigate salt build-up in the soil.

36. Phase transformation

Implement an effect developed during the phase transition of a substance, for instance, during the change of volume, liberation or absorption of heat.

Example: Irrigation VFD drives are cooled with irrigation water piped though a radiator device with irrigation water under pressure. Solvent weld PVC primers and glue.

37. Thermal expansion

Use a material which expands or contracts with heat. Use various materials with different coefficients of heat expansion.

Examples: To control the opening of roof windows in a greenhouse, bimetallic plates are connected to the windows. A change in temperature bends the plates, causing the window to open or close. To control equipment engine temperature an engine thermostat is use and operates on temperature of coolant water inducted to a metal spring and valve.

38. Use strong oxidizers

Replace normal air with enriched air, Replace enriched air with oxygen.

Examples: To obtain more heat from an acetylene torch, oxygen is fed to the torch instead of atmospheric air, to enrich and add power to the internal combustion engine turbo-charges and superchargers are use to push more air into the combustion chambers.

39. Inert environment

Replace the normal environment with an inert one or carry out the process in a vacuum.

Example: To make some turf chemicals easy to handle and mix with water, inert water-soluble ingredients are added to active ingredients.

40. Composite materials

Replace a homogeneous material with a composite one.

Example: Military aircraft wings are made of composites of plastics and carbon fibers for high strength and low weight.

Conclusion

The examples above are not necessarily technologies born form TRIZ theory but the value of a thought process to bring about change and improvement in a repeatable fashion is something that should be considered.

Phases like “Thinking Outside the Box”, “Change is the Only Constant” and “Paradigm Sifting” have been thrown around around like a football on Thanksgiving. The most successful leaders in their field will be the ones that solve the basic problems fast and the complicated problems faster than their competition.

The best way to learn and explore TRIZ is to study the process and begin a problem that you haven't solved satisfactorily!

Subscribe to:

Posts (Atom)